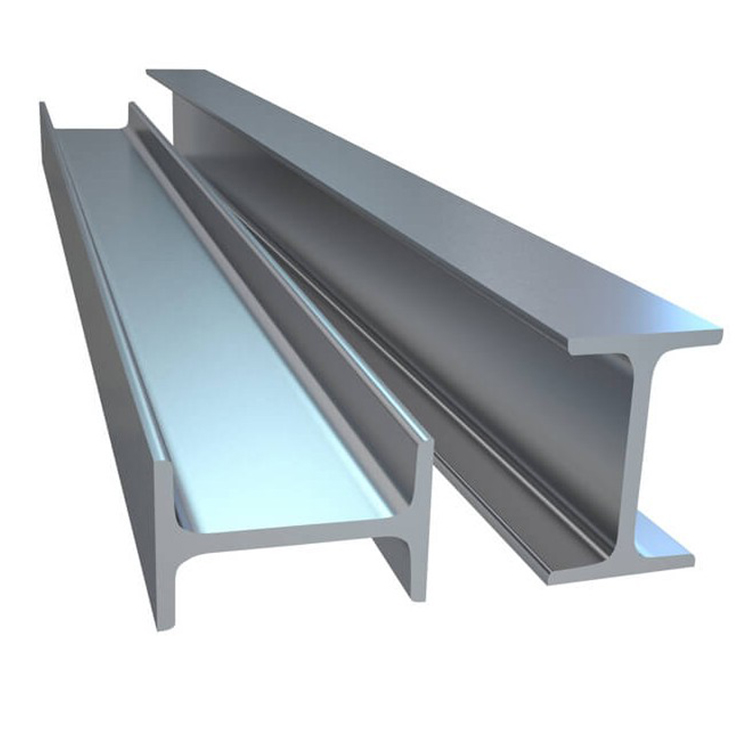

热轧H型钢用途和应用范围特点

2019-06-25

热轧H型钢钢,翼缘宽,侧向刚度大; 抗弯能力强,比工字钢大约5~10%,翼缘两表面相互平行,构造方便。

工业与民用建筑钢结构中的梁、柱构件。

工业构筑物的钢结构承重支架。

地下工程的钢桩及支护结构。

石油化工及电力等工业设备结构。大跨度钢桥构件。

船舶、机械制造框架结构。

火车、汽车、拖拉机大梁支架。

港口传送带、公路档板支架。

热轧H型钢根据不同用途合理分配截面尺寸的高宽比,具有优良的力学性能使用性能。

★结构强度高。同工字钢相比,截面模数大,在承载条件相同时,可节约金属10-15%。

★设计风格灵活、丰富。在梁高相同的情况下,钢结构的开间可比混凝土结构的开间大50% ,从而使建筑布置灵活。

★结构自重轻。与混凝土结构自重相比轻,结构自重的降低,减少了结构设计内力,可使建筑结构基础处理要求低,施工简便,造价降低。

★增加结构使用面积。与混凝土结构相比,钢结构柱截面面积小,从而可增加建筑使用面积,视建筑不同形式,能增加使用面积4-6%。

★与焊接H 型钢相比,能明显地省工省料,减少原材料、能源和人工的消耗,残余应力低,外观和表面好。★便于机械加工、结构连接和安装,还易于拆除和再用。

★采用H 型钢可以保护环境,具体表现在三个方面:一是和混凝土相比,可采用干式施工,产生的噪音小,粉尘少;二是由于自重减轻,基础施工取土量少,对土地资源破坏小,此外大量减少混凝土用量,减少开山挖石量,有利于生态环境的保护;三是建筑结构使用时间到期后,结构拆除后,

★以热轧H 型钢为主的钢结构工业化制作程度高,便于机械制造,集约化生产,精度高,安装方便,可以建成真正的房屋制作工厂、桥梁制作工厂、工业厂房制作工厂等。 ★工程施工速度快,占地面积小,且适合于全天候施工,受气候条件影响小。

相关产品

相关新闻

- 2019-11-04H型钢与其他型钢的对比分析

- 2019-10-22H型钢的使用注意事项是什么

- 2019-09-24H型钢最突出的性能优势是什么

- 2019-07-23工字钢与H型钢有什么区别?