H型钢生产方法

2019-06-18

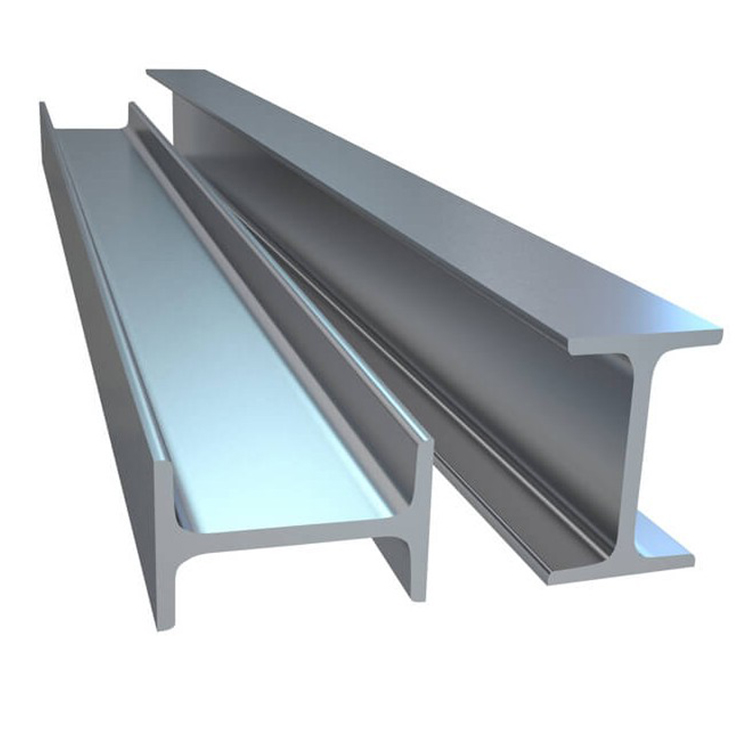

H型钢是一种截面面积分配更加优化、强重比更加合理的经济断面高效型材,因其断面与英文字母“H”相同而得名。由于H型钢的各个部位均以直角排布,因此H型钢在各个方向上都具有抗弯能力强、施工简单、节约成本和结构重量轻等优点,已被广泛应用。

断面形状类似于大写拉丁字母H的一种经济断面型材,又叫万能钢梁、宽缘(边)工字钢或平行翼缘工字钢。H型钢的横断面通常包括腹板和翼缘板两部分,又称为腰部和边部。

H型钢的翼缘内外侧平行或接近于平行,翼缘端部呈直角,因此而得名平行翼缘工字钢。H型钢的腹板厚度比腹板同样高的普通工字钢小,翼缘宽度比腹板同样高的普通工字钢大,因此又得名宽缘工字钢。由形状所决定,H型钢的截面模数、惯性矩及相应的强度均明显优于同样单重的普通工字钢。用在不同要求的金属结构中,不论是承受弯曲力矩、压力负荷、偏心负荷都显示出它的优越性能,可较普通工字钢大大提高承载能力,节约金属10%~40%。H型钢的翼缘宽、腹板薄、规格多、使用灵活,用于各种桁架结构中可节约金属15%~20%。由于其翼缘内外侧平行,缘端呈直角,便于拼装组合成各种构件,从而可节约焊接、铆接工作量25%左右,能大大加快工程的建设速度,缩短工期。

由于具有上述优点,H型钢应用广泛,主要用于:各种民用和工业建筑结构;各种大跨度的工业厂房和现代化高层建筑,尤其是地震活动频繁地区和高温工作条件下的工业厂房;要求承载能力大、截面稳定性好、跨度大的大型桥梁;重型设备;高速公路;舰船骨架;矿山支护;地基处理和堤坝工程;各种机器构件。

H型钢的产品规格很多,分类方法有以下几种。(1)按产品的翼缘宽度分为宽翼缘、中翼缘和窄翼缘H型钢。宽翼缘和中翼缘H型钢的翼缘宽度B大于或等于腹板高度H。窄翼缘H型钢的翼缘宽度B约等于腹板高度H的二分之一。(2)按产品用途分为H型钢梁、H型钢柱、H型钢桩、极厚翼缘H型钢梁。有时也将平行腿槽钢和平行翼缘丁字钢也列入H型钢的范围。一般以窄翼缘H型钢作为梁材,以宽翼缘H型钢作为柱材,据此又有梁型H型钢和柱型H型钢之称。(3)按生产方式分为焊接H型钢和轧制H型钢。(4)按尺寸规格大小分为大、中、小号H型钢。通常将腹板高度H在700mm以上的产品称为大号、300~700mm的称为中号,小于300mm的称为小号。至1990年末,世界上最大的H型钢腹板高度1200mm,翼缘宽度为530mm。

国际上,H型钢的产品标准分为英制系统和公制系统两大类。美、英等国采用英制,中国、日本、德国和俄罗斯等国采用公制,尽管英制和公制使用的计量单位不同,但对H型钢则大都用4个尺寸表示它们的规格,即:腹板高度h、翼缘宽度b、腹板厚度d和翼缘厚度t。尽管世界各国对H型钢尺寸规格大小的表示方法不同。但所生产的产品尺寸规格范围及尺寸公差相差不大。

H型钢可用焊接或轧制两种方法生产。焊接H型钢是将厚度合适的带钢裁成合适的宽度,在连续式焊接机组上将翼缘和腹板焊接在一起。焊接H型钢有金属消耗大、不易保证产品性能均匀、尺寸规格受限制等缺点。因此,H型钢以轧制方法生产为主。在现代化的轧钢生产中,使用万能轧机轧制H型钢。H型钢的腹板在上下水平辊之间进行轧制,翼缘则在水平辊侧面和立辊之间同时轧制成形。由于仅用万能轧机尚不能对翼缘边端施以压下,这样就需要在万能机架后设置轧边端机,俗称轧边机,以便对翼缘边端给予压下并控制翼缘宽度。在实际轧制操作中,把这两座机架作为一组,使轧件往复通过若干次(图2a),或者是令轧件通过由几架万能机座和一两架轧边端机座组成的连轧机组,每道次施加一定的压下量,将坯料轧成所需规格形状和尺寸的产品。在轧件的翼缘部位,由于水平辊侧面与轧件之间有滑动,轧辊的磨损比较大。为了保证重车后的轧辊能恢复原来的形状,应使粗轧机组上下水平辊的侧面以及与其相对应的立辊表面呈3°~8°的倾角。为修正成品翼缘的倾角,设置成品万能轧机,又叫万能精轧机,其水平辊侧面与水平辊轴线垂直或有较小的倾斜角,一般不大于20′,立辊呈圆柱状

用万能轧机轧制H型钢,轧件断面可得到较均匀的延伸,翼缘内外侧轧辊表面的速度差较小,可减轻产品的内应力及外形上的缺陷。适当改变万能轧机的水平辊和立辊的压下量,便能获得不同规格的H型钢。万能轧机的轧辊外形,形状简单,寿命长,轧辊的消耗可大为减少。万能轧机轧制H型钢的最大优点是: 同一尺寸系列只有腹板和翼缘的厚度尺寸是变化的,其余部位尺寸都是固定不变的。因此,同一万能孔型轧制的同一系列H型钢具有多种腹板和翼缘厚度尺寸规格,使H型钢规格数量大为增加,为使用者选择合适的尺寸规格带来极大的方便。

在无万能轧机的情况下,有时为了满足生产建设的急需,也可将普通二辊式轧机加装立辊框架,组成万能孔型轧制H型钢。用这种方式轧制H型钢,产品尺寸精度低,翼缘同腹板之间难成直角,成本高,规格少,轧制柱材用H型钢极为困难,故使用者不多。

相关产品

相关新闻

- 2022-05-13批发市场分享H型钢不光滑的原因

- 2022-04-14 h型钢的材质主要Q235B Q345B钢结构H型钢

- 2022-03-25H型钢的HT是什么意思,代表什么,T是什么意思

- 2022-02-15H型钢结构介绍